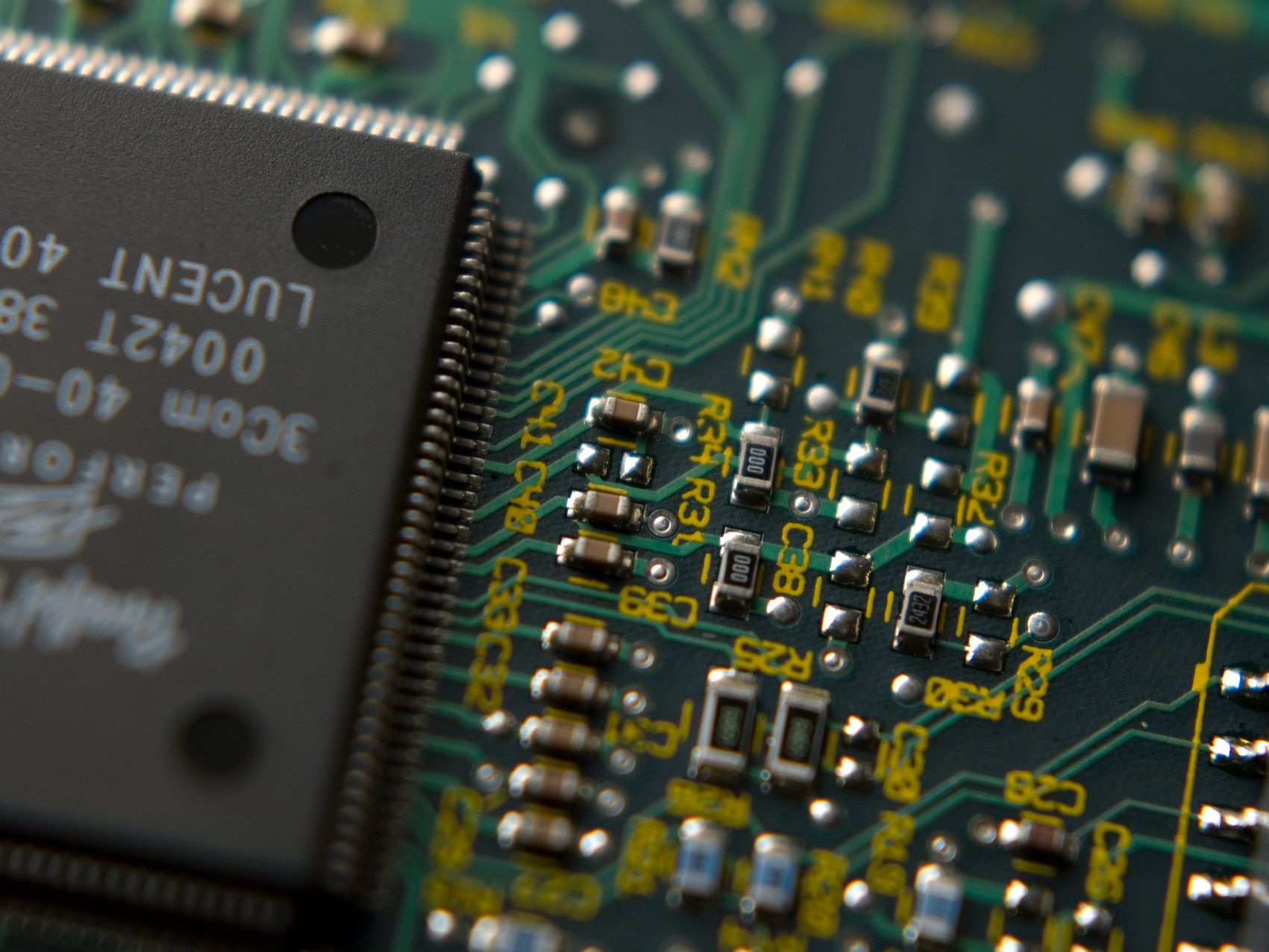

Design Linked Incentive Scheme and chip making industry in India

Why in news?

India has invited applications from 100 domestic companies, startups and small and medium enterprises to become a part of the design-linked incentive (DLI) scheme.

Along with it the IT ministry has sought proposals from academia, start-ups and MSMEs to train 85,000 qualified engineers on semiconductor design and manufacturing.

Along with it the IT ministry has sought proposals from academia, start-ups and MSMEs to train 85,000 qualified engineers on semiconductor design and manufacturing.

Background

70% of the world’s semiconductors are produced by few companies based in Taiwan and South Kores.

The European union announced public-private semiconductor alliance with the goal of increasing Europe’s chip production share to 20% by 2030.

In backdrop of this to boost production of semiconductors Indian government has announced a DLI Scheme.

The DLI scheme aims to provide financial and infrastructural support to companies setting up semiconductor plants in India.

It will offer fiscal support of up to 50% of the total cost to eligible participants as well as offer fiscal support of 30% of the capital expenditure to participants building compound semiconductors, silicon photonics and sensors fabrication plants in India.

The European union announced public-private semiconductor alliance with the goal of increasing Europe’s chip production share to 20% by 2030.

In backdrop of this to boost production of semiconductors Indian government has announced a DLI Scheme.

The DLI scheme aims to provide financial and infrastructural support to companies setting up semiconductor plants in India.

It will offer fiscal support of up to 50% of the total cost to eligible participants as well as offer fiscal support of 30% of the capital expenditure to participants building compound semiconductors, silicon photonics and sensors fabrication plants in India.

Objectives of Design Linked Incentive Scheme

- Provide financial and infrastructural support to companies setting up fabs or semiconductor making plants in India.

- Offer fiscal support of up to 50% of the total cost to eligible participants who can set up these fabs in India.

- Offer fiscal support of 30% of the capital expenditure to participants for building compound semiconductors, silicon photonics and sensors fabrication plants in India.

- An incentive of 4% to 6% on net sales will be provided for five years to companies of semiconductor design for integrated circuits, chipsets, system on chips, systems and IP cores.

- It is expected to facilitate the growth of at least 20 such companies which can achieve a turnover of more than ₹1500 crore in the coming five years.

Benefits

- Avoid high dependencies on a few countries or companies for semiconductor chips and devices.

- The start of new companies will help in meeting the demand and supply and encourage innovation in India.

- Attract existing and global players in semiconductor industry as it will support their expenditures related to design software, IP rights, development, testing and deployment.

- Boost the domestic companies, start-ups, and MSMEs to develop and deploy the semiconductor design.

- Help global investors to choose India as their preferred investment destination.

Global Scenario

Semiconductor manufacturing is dominated by companies in the U.S., Japan, South Korea, Taiwan, Israel and the Netherlands. They are also making efforts in solving the chip shortage problem.

U.S President wants to bring manufacturing back to America and reduce the country’s reliance on a small number of chipmakers based largely in Taiwan and South Korea.

South Korea has offered various incentives to attract $450 billion in investments by 2030.

U.S President wants to bring manufacturing back to America and reduce the country’s reliance on a small number of chipmakers based largely in Taiwan and South Korea.

South Korea has offered various incentives to attract $450 billion in investments by 2030.

Challenges for India

- Setting up fabs is capital intensive and needs investment in the range of $5 billion to $10 billion.

- Lack of investments and supportive government policies are some of the challenges to set up fabs in India.

- New fabs use sub 5 nano meter technology that requires clearance from both the technology provider and the Government a combination of capital and the geopolitical situation comes into play to build new fabs.

- Infrastructural issues like connectivity to airports, seaports and availability of gallons of pure water.

Conclusion

The Design Linked Incentive (DLI) scheme along with the recent Production-Linked Incentive (PLI) scheme have become crucial in shaping India as an efficient, equitable, and resilient design and manufacturing hub.